- Automatic Roll Mesh Welding Machine

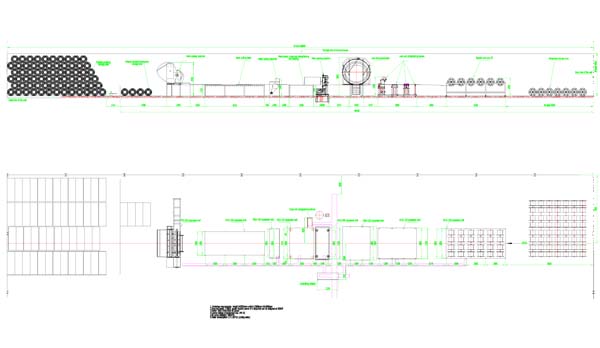

Layout of Steel bar coil mesh welding machine

Reinforcement mesh production line for the wire fed from coils

Reinforcing mesh welding line for coil mesh

Mesh straightening part and accumulator Mesh Welding Machine

Mesh out puller of reinfrocing mesh welding machine

- 01. Introduction of auomatic roll mesh welding machine

- 4-8mm reinforcing mesh welding machine is the specialized equipment for wire mesh fence that the wire are feed in pre-straightened and cut. This machine welds the line wires and cross wires of the steel to be solid mesh in the principle of multi-electrode resistance welding.

It consists of welded equipment, line and cross wires feeding device, mesh stepping system, mesh laying and convey device, pneumatic system, electrical control system and cooling system. The material can be rolled ribbed steel wire, cold or hot rolled round steel wire. Working process of the pre-cut reinforcing mesh welding line: line wire is put in place automatically, cross wire is blanking automatically, pneumatic cylinder goes down start power to weld remain the power cut-off, pneumatic cylinder goes up, the mesh took away from the electrode by the system, servo motor drives the mesh to needed place, cross wire is blanking automatically.

- 02.Technical parameter

-

Max width of the panel mesh2500mmMax length6000 mmLine wire spacing100mmCross wire spacing50mm, freely programmable spacingWire diameterLine wire4-8mmCross wire4-8mm.Feeding wayLine wireIn coilsCross wireIn coilsNumber of welder point24 pointsMax. welding speed55-70 meshes/minuteWater cooling transformer6X150KVAPower380V, 50HzAir consumption≥0.8Mpa, 2m3/minCooling water consumption≥0.3Mpa, 3m3/minMachine overall dimension60m(L) × 8m(W) × 5m(H)Machine overall weight25,000Kg