- Razor Barbed Wire Machine

- Home > Our products

Razor barbed wire machine

Barbed wire making machine

Protective fence barbed wire machine

Razor wire machine

Protective fence barbed wire machine

- 01. Introduction of single barbed wire machine

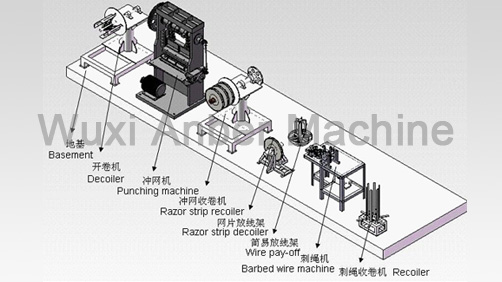

- This production line is composed of decoiler, punching machine, decoil intermittence device, razor strip coiler, steel wire pay-off rack, razor strip decoiler, barbed wire machine, barbed wire recoiler, electric control cabinet and so on.

- 02.Machine main parameter

- Inner diameter of the steel strip Decoiler: 300 mm (adjustable)

Steel strip loading weight: 300kg

Punching speed: 200 seconds/Min

Punching mold: Effective distance: 10mm, material: Cr12MOV, hardness: HRC58-62

Punching motor power: 4KW

Razor strip coiler power: 0.9KW

Inner diameter of wire pay-off: 440 mm

Barbed wire machine drive pattern: Chained gear

Barbed wire machine motor power: 2.2KW

Barbed wire machine speed-reducer power: 1.1 KW

Forming roller Quantity: 2groups, diameter: 110mm, 69mm

- 03. Machine structure description

This production line is composed of decoiler, punching machine, decoil intermittence device, razor strip coiler, steel wire pay-off rack, razor strip decoiler, barbed wire machine, barbed wire recoiler, electric control cabinet and so on.

Decoiler: passive decoil, simply structured.

Decoil intermittence device: installed and fasten on the punching machine, adopts lever principle, one end of rod pressed on razor strip, when tension is excessive, the other end will press down on the switch touch to stop the decoiler. When tension is decreased, razor strip drops down to a certain degree, rod will press down the upper process switch touch, at this time, motor starts to work again.

Razor strip machine: Motor drives belt to transfer power to crankshaft, then crankshaft drives mould move up and down at high speed. At the same time, the crankshaft moves to drive feeding system to match the punching movement.

Razor strip recoiler: reducer motor drives belt gear to transfer recoiling power, and adopts the damp structure to prevent the inertia force when rolling movement stops.

Steel wire pay-off: decoiling power supplied by barbed wire machine.

Razor strip decoiler: It is welded from rectangular tube, adopts passively decoil, the structure is simple and the operation is convenient.

Barbed wire machine: powered by electromagnetic speed regulation motor, its belt wheel at the bottom connects with barbed wire machine and Synchronous.

Decoiler: passive decoil, simply structured.

Decoil intermittence device: installed and fasten on the punching machine, adopts lever principle, one end of rod pressed on razor strip, when tension is excessive, the other end will press down on the switch touch to stop the decoiler. When tension is decreased, razor strip drops down to a certain degree, rod will press down the upper process switch touch, at this time, motor starts to work again.

Razor strip machine: Motor drives belt to transfer power to crankshaft, then crankshaft drives mould move up and down at high speed. At the same time, the crankshaft moves to drive feeding system to match the punching movement.

Razor strip recoiler: reducer motor drives belt gear to transfer recoiling power, and adopts the damp structure to prevent the inertia force when rolling movement stops.

Steel wire pay-off: decoiling power supplied by barbed wire machine.

Razor strip decoiler: It is welded from rectangular tube, adopts passively decoil, the structure is simple and the operation is convenient.

Barbed wire machine: powered by electromagnetic speed regulation motor, its belt wheel at the bottom connects with barbed wire machine and Synchronous.