- 5 Strips Razor Barbed Wire Machine

- Home > Our products

Prison fence machine

Barbed rope machine

Barbed wire tape machine

Razor barbed wire making machine

Barbed wire machine

- 01. Main performances and characteristics

- Razor barbed wire is common safe operation material, it has advantages that strong sharp, easy to construct, low cost and so on. Razor barbed wire machine is a special equipment to manufacture razor barbed wire, it has advantages that operate simply, safety, efficient production, adapt to many sorts and so on.

- 02.Material requirements and barbed wire application

- Finished products of razor barbed wire machine (production line) are used for all kinds of special places and temporary barriers of protective materials.

Its’ material are galvanized plate that 0.3-0.6mm in thick and diameter from 1.5-3.5mm galvanized iron wire.

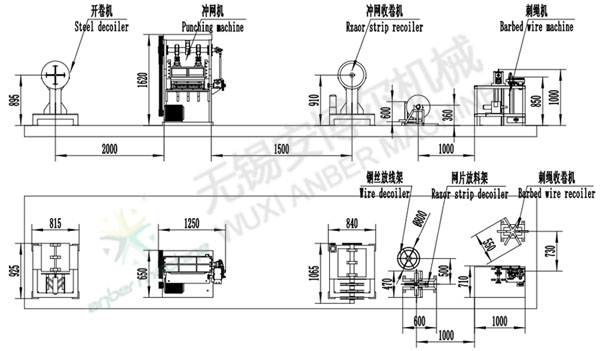

- 03. Composition and function of the equipment

Razor barbed wire machine is made of two parts that blade shearing equipment and composite wire for blade thorn rope molding equipment.

Blade shearing equipment is used for producing composite blade thorn rope when needed for the thorn.

Molding equipment the blade and blade thorn rope in galvanized wire in products.

1. Razor punching machine includes pay-off, punching and shearing equipment, blade separation machine and re-coiler. Punching and shearing equipment is composed of press machine, servo feeding and mould.

Pay-off is used for storing and offering punching and shearing material; Servo feeding device offer galvanized plate to punch as certain rhythm and the specific length; Press machine and mould are used for shearing galvanized plate to blade; Re-coiler is used for dividing shearing blade into 5 stripes, rolls around.

2. Forming machine contains blades and pay-off that feeding galvanized iron wire, compound with the molding machine and re-coiler.

Blade shearing equipment is used for producing composite blade thorn rope when needed for the thorn.

Molding equipment the blade and blade thorn rope in galvanized wire in products.

1. Razor punching machine includes pay-off, punching and shearing equipment, blade separation machine and re-coiler. Punching and shearing equipment is composed of press machine, servo feeding and mould.

Pay-off is used for storing and offering punching and shearing material; Servo feeding device offer galvanized plate to punch as certain rhythm and the specific length; Press machine and mould are used for shearing galvanized plate to blade; Re-coiler is used for dividing shearing blade into 5 stripes, rolls around.

2. Forming machine contains blades and pay-off that feeding galvanized iron wire, compound with the molding machine and re-coiler.

- 04. Razor punching machine

- 05. Barbed wire clasping machine

Item |

Name |

Specification |

Qty |

1 |

Pay-off |

Inner diameter: 500mm Adjustable Outer diameter: 1000mm Loading weight: 500Kg Motor power: 25W, Rotation speed: 1400r/min Size of Decoiler: 700×700×1230mm Total weight: 500kg |

1Set |

2 |

Punching machine |

Weight: 500Kg Normal force: 250KN Nominal Stroke: 4mm Slide block stroke : 8 mm Times of sliding block stroke: 202 times/min Max Die Set Height: 160 mm Die Height Adjustment: 40 mm Size of working table: 760mmX500mm Motor power:7.5KW, Rotation speed: 1450r/min Size of punching machine: 1300×880×1650mm Total weight: 1100kg |

1Set |

3 |

Blade divided device |

2Set |

|

4 |

Recoiler |

Recoil Inner diameter: 100mm Recoil Outer diameter: 550mm Recoil loading weight: 500Kg Recoil Motor Power: 0.75W, Rotation speed: 1400r/min Size of machine: 700×980×970mm Total Weight: 500Kg |

1 set |

Item |

Name |

Specification |

Qty |

1 |

Pay-off |

Use blade and galvanized iron wire | 2Set |

2 |

Forming machine |

Adaptive thickness: 0.3~0.5mm Adaptive wire diameter: φ1.5~φ3.5mm complex speed: 12m /Min Adjustable Motor power: 3KW, Rotation speed: 1420r/min Size of machine: 1000×930×1230mm Weight: 200Kg |

1Set |

3 |

Re-coiler |

Inner diameter: 450mm Adjustable Outer diameter: 450+200mm Loading weight: 500Kg Size of equipment: 700×700×850mm Weight: 50Kg |

1Set |