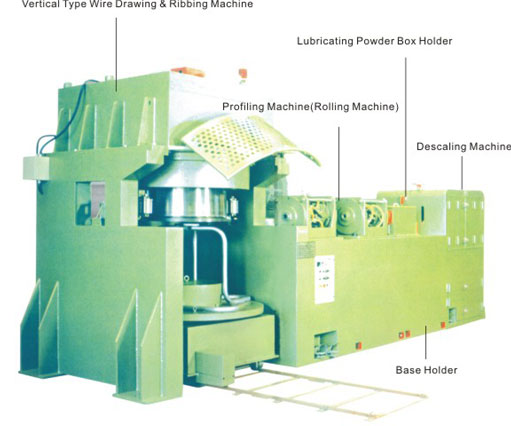

- Vertical Type Wire Drawing & Ribbing Machine

- 01. Machine sample

- 02. Features

This machine is a vertical type single drum wire drawing machine.As for drawing wire rod. this machine is also equipped with descaler to save the acid washing process to attain the goal for effort-saving, cost reduction and public harm free.

With two sets of pattern rollers, this machine is sultable for steel wire drawing and profiling. The finished products can be coiled on the wire stand underneath the machine for easy unloading. This machine is simple in operation and is equipped with one set of die for interchange with the pattern rollers.

With two sets of pattern rollers, this machine is sultable for steel wire drawing and profiling. The finished products can be coiled on the wire stand underneath the machine for easy unloading. This machine is simple in operation and is equipped with one set of die for interchange with the pattern rollers.

- 03. Standard equipment

- Vertical type wire drawing & ribbing machine (GVY-750TW)

1. This machine is equipped with an AC motor of 100HPX4P/6P with stepless speed variation in conjunction with a transducer.

2. The feeding wire diameter is 13mm-5.5mm, while the finished wire diameter is 10mm-4.0mm. The tensile strength of the wire rod is below 52kg/mm2

3. Wire drawing speed is 135 m/min (Max). Please refer to Mold Arranging Table.

4. Diameter of drawing drum is 750 mm and the drawing drum is treated with hot surface spraying welding and case-hardening with water inside for circule cooling.

5. The gear box uses worm gear for transmission and oil dipping for lubrication.

6. Two groups of wire pressing wheel which is made of SKD-11 heat-treated.

7. The material handling rack is equipped with AC motor of 2HPX4P4P/6P for stepless speed variation in conjunction with the inverter(frequency changer) and linked in proportional movement with the main motor.

8. Material rack operating cylinder of which the max. loading is 1300kg .

9. Brake system: DISCO Brake is used for drawing drum and air brake is used for the material arranging rack.

10. Electrical control system: Counter, Wire Speed Gauge, Alarm, "Inching" speed adjusting knob, fine tuning knob, emergency brake and safety device.

Wire rob releasing stand

1. The effective circumference of the the stand is 1700mm, its hight is 2650 mm and its maximum loading is 2000kg.

2. Rotation sensitivity adjuster which is used to fasten or loosen the wire rod releasing stand.

3. Brake device which is used to stop the releasing stand from inertial moving when the machine is shut down.

4. Entanglement detector which is used to stop the machine upon the wire is in disorder.

5. Wire releasing frame, its size is 1450mm X 750mm X 2000mm(Max.).

Profiling machine (rolling machine)

1. Two groups of rolling machine with front-rear mounting, totalling 6 rollers, of which the diameter can be adjusted depend on the diameter of the finished products.

2. Rollers are made of tungsten carbide and the mandrel is fillled with water for cycle cooling.

Lubricating powder box holder

The lubricating powder is only supplied for lubricating the rolling machine during ribbing operation. Powder screw is mounted in the lubrication powder box for feeding the powder to the inleting wire head thus obtaining the uniform lubrication effect.

Descaling machine

This descaler can be used for stripping the wire below 13mm in diameter.This descaler is characterized in bending the wire without man-power and the motor attached to it can be used to bend the wire at required angle(Max.180). With the bending force, this descaler can strip off the metal dust on the wire. This strip wheel is made of ceramic material with high wear resistance thus extending its service life.

Drawing dies box

Drawing dies can be placed in the die box, die box can be filled with cooling water and the lubrication powder can be placed at the trailing edge of the drawing dies box for lubricating the drawing die. The specification of the drawing dies "W106 "W107" W108" and the wire breaking detector is installed on the front part of the drawing die box.

Base holder

This base holder is mainly used for installation of the frame required by rolling machine, drawing dies box and lubricating powder box, the number of the base holder needed depends on the purpose of producion.