- Accessory Machines For Wire Drawing Machine

- 01. Wire unloading machine

-

This unit belongs to ordinary non-stop wire coiling machine which is equipped with a die box for making skin pass. The wire feeding device is lifted lower by a cylinder for easier wire set up. This machine is most idea for final process of screw wire.

Model: ABE-600B(SKIN)

Drawing material: Low carbon steel

Drawing capstan dia.: 600 mm

Wire inlet dia.: 4.6-1.8

Wire final dia.: 4.4-1.6

Drawing speed: MAX. 270 m/min

Power required/Block: 25HP-20HP

Model: ABE-700B(SKIN)

Drawing material: Low carbon steel

Drawing capstan dia.: 600 mm

Wire inlet dia.: 5.5-1.8

Wire final dia.: 5.3-1.6

Drawing speed: MAX. 270 m/min

Power required/Block: 25HP-20HP

- 02. Wire straightening & cutting machine

-

Mechanical wire straightening and cutting machine is mainly used to straight and cut the wire to feed in the fencing mesh welding machine that the wire diameter is small.

Normally the mechanical type wire straightening and cutting machines are of low speed, but ANBER do some design to impreove the machine technology, so that the straightening and cutting speed can reach 80m/min.Model: ABE-MT3/5

Wire Dia.: φ3-φ5mm

Cutting length.: 1-6 m, or according to customers requirement

Straightening ratio: ≤2 mm/m

Max. speed : 80m/min

Cutting tolerance: 5 mm

Total power: 3kw

Overall size: 12004201200mm

Model: ABE-MT4/8

Wire Dia.: φ4-φ8mm

Cutting length.: 1-6 m, or according to customers requirement

Straightening ratio: ≤2 mm/m

Max. speed : 80m/min

Cutting tolerance: 5 mm

Total power: 4 kw

Overall size: 12004201200mm

- 03.Well type annealing furnace

-

Main parameter:

Motor: 60 KW, 380 V, 3 phase

Rated temperature: 950oC

Connecting form: YY

Heating area:2

Vacant furnace power comsumption:18KW

Vacant furance temperature rising time: 3.5 hours

Max. load: 1100kg

Stock bin size: O800*1600 mm

Weight:4800kg

Overall size:2000*2000*2500 mm

- 04.Wire descaling machine

-

Main parameter:

Max. wire dia.: φ8 mm

Capstan dia.: φ600 mm

Descaling speed: 150 m/min

Capstan rotation speed: 80 rpm

Wire speed: 77.5 mm/min

Motor: Y-160M-6-7.5 KW

Reducer: JZQ-400i=23.34

Weight:3000 kg

Overall size: 3130*1080*1020 mm

- 05.Wire pointing machine

-

This wire pointing machine is a kind of wire head roller and is suitable for rolling soft wire and mid-carbon wire 13m/m in diameter. It is also called tip roller, wire pointer. The operation of this machine is very simple and convenient.

Model: ABE-3

Finished wire dia.: φ0.8-φ3

R.P.M: 58

Power required:1/2HP

Model: ABE-6

Finished wire dia.: φ1.5-φ5.5

R.P.M: 64

Power required:2HP

Model: ABE-13

Finished wire dia.: φ5-φ13

R.P.M: 43

Power required:5HP

Model: ABE-25

Finished wire dia.: φ13.5-φ25

R.P.M: 29

Power required: 7.5HP/1HP

Model: ABE-36

Finished wire dia.: φ24.5-φ36

R.P.M: 24

Power required: 15HP/2HP

- 06.Spooler take-up

-

Wire Spooler take-up can coil the wire layer by layer, the coiled wire will be tight and no chaos.

Take-up Material: Low, medium or high carbon steel, stainless steel or other non-ferrous

Model: BN-800

Spooler Size: 800X400X500(ODXIDXW)

Wire Inlet Dia.: 3.0-0.8

Working speed: 400 M/Min-800 M/Min

Power required/capstan: 30 HP/1HP

Model: BN-500

Spooler Size: 630X355X400(ODXIDXW)

Wire Inlet Dia.: 1.2-0.7

Working speed: 400 M/Min-600 M/Min

Power required/capstan: 15 HP/1 HP

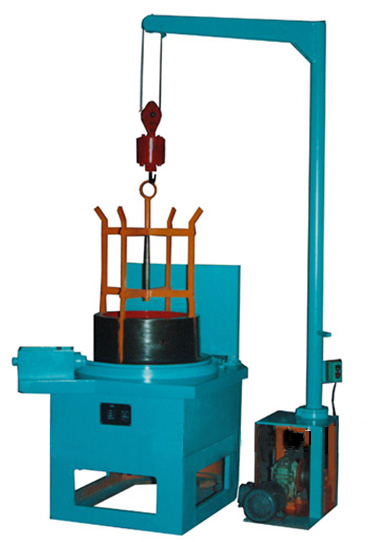

- 07.Discharging machine

-

Model NO.: ABE-LFX001

Max. hoisting capacity: 500 kg

Lift distance: 2650 mm

Lift speed: 2650 mm

Beam over handing distance: 1230 mm

Motor power: 2.2 KW

Total weight: 600 kg

Model NO.: ABE-LFX002

Max. hoisting capacity: 350 kg

Lift distance: 2500 mm

Lift speed: 2500 mm

Beam over handing distance: 1085 mm

Motor power: 1.1 KW

Total weight: 300 kg

- 08.Butt welding machine

-

This butt welding machine, which is also called butt welder, is mainly used for butt welding(joint) of frame wire. Its performance: Convenient operation, materail saving and stable performance.

Model: UN-1-4

Welding range: φ0.8-φ3 (Copper), φ1-φ4 (Iron)

Power: 3KW

Model: UN-2-6.5

Welding range: φ4 (Copper), φ2-φ6.5 (Iron)

Power: 5KW

Model: UN-3-8

Welding range: φ5 (Copper), φ3-φ8 (Iron)

Power: 7KW

Model: UN-4-10

Welding range: φ6 (Copper), φ4-φ10 (Iron)

Power: 10KW

Model: UN-10-14

Welding range: φ8 (Copper), φ10-φ14 (Iron)

Power: 25KW

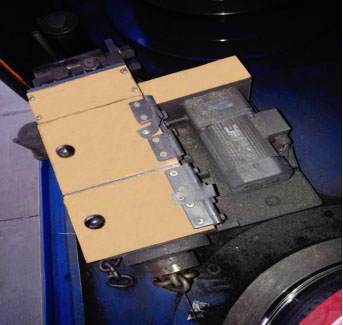

- 09.lubricate applicator

Adjustable wire clamp

Drawing powder applicator

High quality lubricant applicator

Lubricant applicator

Powder clamp

-

Specifications

Lube Applicator is very easy to use. It is simply to be clamped on to the wire in the die box, thus avoiding the cumbersome process of threading.

Features

1. simple structure, easy operation and flexible motion

2. Prevent wire scratching

3. Increase wire drawing die life

4. Higher speed

5. Reduce wire breaks

6. Uniform surface finish

Weight: 2.5kg

Size: 200*100*68mm

- 10.Rotary die box

-

The rotary die box includes a lubrication box and a mold box. Lubricant powder is contained in the lubrication box. The mold box is provided with a drawing die rotating device, and a drawing die is arranged in the mold box. The wire drawing die is between the top wire and the hollow shaft. The rotation of the hollow shaft can drive the wire drawing die to rotate together, thereby avoiding the excessive damage to a point or a region of the inner surface of the drawing die due to the uneven shape of the wire surface or the hard particles on the surface. This makes wear on the inner surface of the drawing die very uniform. The life of the wire drawing die is improved, and the quality of the produced product is more stable.

- 11.Borax (pretreatment) production line

-

Flow chart:

Mechanical peeling & derusting unit → Steel wire ball strong force cleaning up unit → Electroanalysis pickling unit → Heating water channel → unit Boron coating unit → Drying unit