- Security Door Powder Coating Line

Safety door powder coating line

Safety guard door powder coating line

Exterior door powder coating line

Interior door powder coating line

Safety guard door powder coating line

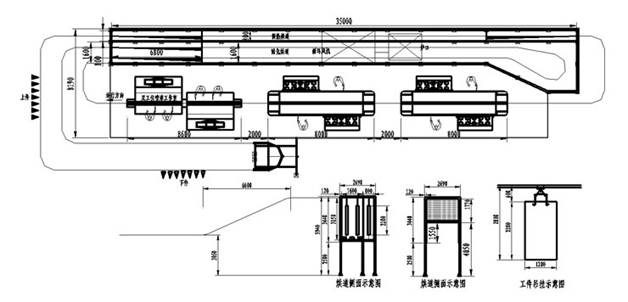

- 01. Typical layout

- 02. Design basis for security door powder coating line

- 1. Name of workpiece: Iron plate for security door

2. Max hanging size on each hanger: L1500mm×W100mm×H2300mm

3. Loading capacity on hanging hook: ≤70kg

4. Suggested interval between 2 hangers: 500mm

5. Conveying speed: 1.5m/min (Adjustable control)

6. Output: 35-45pcs per hour

7. Spraying method: 4 auto spray guns (match on 2 reciprocators) & 2 manual spray guns

8. Heating source: natural gas (Other choices are available: electricity, oil or coal)

9. Pretreatment system: Vertical shower type

- 03. Process flow for safety door powder coating line

- 1. Feed your security door on this automatic powder coating line

2. Pre-degreasing stage (50-65 Celsuis for 1 min)

3. Degreasing stage (50-65 Celsuis for 2 mins)

4. Rinsing stage (Room temperature for 1-2 mins)

5. Surface conditioning stage (Room temperature for 1 min)

6. Phosphating stage (35-45 Celsuis for 3 mins)

7. Rinsing stage (Room temperature for 1-2 mins)

8. Drying off oven to remove surface moisture (100-120 Celsuis for 10 mins)

9. Powder application with spray guns

10. Powder curing (180-200 Celsuis for 20 mins)

11. Finished product discharging

If above parameters cannot meet with your strict coating need, please contact us for more detail. We can make some adjustments or even improvements to suit your actual production conditions.