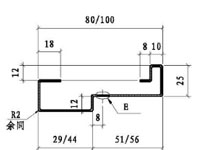

- Security Door Frame Roll Forming Machine

Door frame roll forming machine

Manual feeding and flattening(servo motor)

Hydraulic servo punching

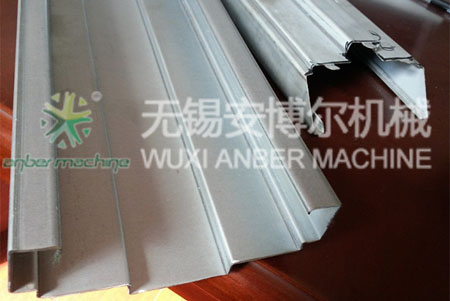

Steel door frame

Raw material for steel door frame

- 01. Description of metal door frame roll forming machine

- Steel doors have always been choice for strength and durability, which result in a finished product of quality and greatest strength, providing much needed security. Door frame roll forming machine is the essential for its production.

This machine is used to produce metal door frame, from a coil to finished door frame product by one production line, the machine line has 3in1 equipment which has de-coiler for coil hold, leveling machine for making coil sheet flat, and then use servo feeder to feed sheet length to punching machine as PLC program setting, hydraulic punching machine has several individual cylinder which could be separately controlled by PLC, so it's easy to achieve punching any hole or slot or notching at any length side of sheet. After finish holes punching on sheet, then do length cut-off, and then use automatic convey belt to transfer the sheet to roll forming machine. Roll forming machine will form the door frame profile as the drawing requirement step by step. After profile forming there has straightening device for adjusting the straightness of finished door frame. And then product comes out of roll forming machine to stand tables ready for packing.

It is full automatic machine line and quite easy to use it, only require 3 people for operation.

- 03. Material specification

- 1. Material type: cold rolled steel, galvanized steel

2. Thickness: 0.8-1.2mm

3. Max. Width: 350mm

4. Yield strength: 195Mpa

- 04. 3in1 machine

- 1. Coil ID: 508mm

2. Coil OD: 1200mm

3. Coil weight: 2 tons

4. Max. Speed: 16m/min

5. Feeding precision: ±0.1mm

6. Expansion type: hydraulic

- 05. Punching machine

- Mold Material: Cr12Mov

Mold Treatment: Heat treatment, HRC58~62.

Control System: PLC control

- 06. Roll forming machine

- Motor power: 11kw;

Motor quantity: 2 sets;

Roller material: Gcr15 bearing steel

Forming station: 18 stations

Forming speed: 10-20m/min

Shaft diameter: 75mm

Shaft material: 40Cr

Transmission type: worm gear box

Dimension(L*W*H): 7.35*1.2*1.5m

Weight: about 3.5T

- 07. Equipment list

- 1. Hydraulic De-coiler with Breaking device is equipped for coil processing.

2. Leveler

3. Servo Roll Feeder

4. Online Multi Station Hydraulic Punching Equipment

5. Roll forming machine

6. Back Punching Machine [for lock hole]

6. Hydraulic cut-off machine

7. Run Out Table or automatic stacking device

8. PLC and Touchable Screen are used for data processing and setting.