- Wire PVC Coating Line

Wire pvc coating line

Wire pvc coating line

Wire pvc coating line

Wire pvc coating line

- 01. Main parameter of pvc coating line

- Wire PVC coating line is used to produce PVC insulated wire, the customer can produce insulated wire of different size by change the machine head and related accessories. The extruder and tractor apply YCT series governor motor with big range of speed adjustment; we use the intelligent temperature control instrument to control the temperature of the capstan and head automatically with high sensitivity. The structure of the production line is simple, easy to operate, safe and reliable.

Screw dia: 65mm

Screw length: 1625mm

Aspect ratio: 25:1

Screw rotate speed: 4-40r/min

Motor: Y160M-4; 11KW

Capstan heating and cooling: 5KW

Machine head heating power: 5KW

Center height of the machine: 1000mm

Machine weight: 450kg

Structure description:

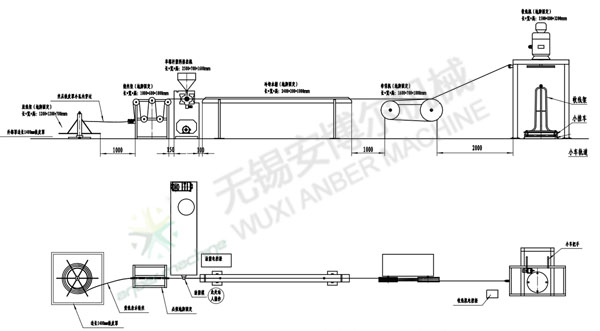

The wire PVC coating line is vertical type and aligned in the straight line, compare with wire pay-off, wire guiding frame, extruder, machine head, water cooling groove, wire take-up and electrical controlling cabinet, etc.

1. Wire pay-off is used to decoil the wire and feed into the wire guiding frame.

2. There is two rolling wheel on the wire guiding frame, the wire go through the wheel will become straight to direct it into the machine head. Another rolling wheel can adjust up and down to confirm the wire center is at the same height with the extruder center.

3. Extruder is the main part of the wire PVC coating production line and it is used for the soft PVC insulate wire. Customer can use this machine to produce pipe, single wire, etc., by change the machine head and related accessories. Extruder is compared of drive system, screw, plastic capstan, plastic feeding system, electric heater, etc.

4. Machine head, located in the front end of the charging barrel, is the forming part of the wire insulating layer. It is composed by mould body, core mould, mouth mould, adjusting screw, etc.

5. There are two cooling flumes, both of which are composed of inlet and outlet water pipes, water valves, flume shelf. The surface layer of the wire, which is out of the mouth mould of the machine head, is shown as soften status. So it must be cooling shaped through cooling flume. The cooling water flows out from the inlet water pipes, and the wires are thoroughly hardened when they pass from the water current. Meanwhile, the hot water is discharged from the return pipes. During the whole process, the cooling water is circulatory.

6. Traction engine: The power of the driven motor on the traction engine is 3KW, after decreasing the speed by the speed reducer, then transmitting by the chain wheels, and then the two traction wheels could rotate. The diameter of the traction wheel is 600mm; the adjusting range of the traction speed is 20-200m/min. In order to prevent the wire from track slipping when traction, the wires are wound as "S" shape in the upper and lower traction wheels, in order to increasing the friction force. The speed-regulating motor is controlled by the assorted speed-regulating motor controller.

7. Recoiling machine: The recoiling machine is driven by one set of three-phase torque motor of YLJ132-40/4 type. This motor could keep the recoiling tensile force the same as the recoiling diameter increasingly becomes bigger. Meanwhile, use the wire arranging unit to arrange the wires automatically, and arrange the wires to the recoiling panel. When one recoiling panel is full of the wires, push the handle in the rack and start another wire recoiling panel. The recoiling panels are used alternatively.

- 03. Products (pvc coated wire)

-

PVC Coated Wire

PVC Coated Wire