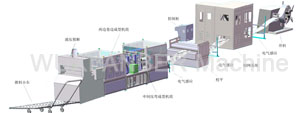

- Low Speed Expanded Battery Plat Mesh Machine

- 01. Introduction of low speed expanded battery plat mesh machine

- Expanded battery plate Production line is fully automatic from material loading and plate produced,and just need one technician to operate,produce 5-7 pcs of 750MM plates per minute. Outsize of the production line is 25MX3.5MX2.2 M.

Electric parts are from first grade brand: PLC and display from Mitsubishi,and other electrical components for the Schneider brand.

The sensors record the movement of raw materials at every parts. Automatic fault report,and security alarm.

The process controls and records daily production,for example,the set production for today is 6000T,the device will stop automatically when the capacity reach 6000T.

- 02. Decoiler

Tension controlled by hydraulic

Motor controls to feed material, and electric elements controls the feeding speed.

Loading weight: 2T, ID: 450-508mm, material width: 400mm

Mesh expanding system

Roll feeding and expanding

Auto lubricated

Auto counting

Mesh straightening machine

7 rollers to straightening the mesh to promise it is flat

The upper rollers are driven by gearbox to adjust the distance of the rollers.

Roller dia.: 96mm

Rollformer

The roll forming part applies 13 groups of rollers

Shaft drives which can reduce error.

Encoder to measure the length

Hydraulic cutting system

Lath collector

To collect and stack the battery plate.

Plate collect trolley

Convenient to transport the battery plate

Controlling system

combination method of the overall control and local debugging agile control

Motor controls to feed material, and electric elements controls the feeding speed.

Loading weight: 2T, ID: 450-508mm, material width: 400mm

Mesh expanding system

Roll feeding and expanding

Auto lubricated

Auto counting

Mesh straightening machine

7 rollers to straightening the mesh to promise it is flat

The upper rollers are driven by gearbox to adjust the distance of the rollers.

Roller dia.: 96mm

Rollformer

The roll forming part applies 13 groups of rollers

Shaft drives which can reduce error.

Encoder to measure the length

Hydraulic cutting system

Lath collector

To collect and stack the battery plate.

Plate collect trolley

Convenient to transport the battery plate

Controlling system

combination method of the overall control and local debugging agile control