|

|

| |

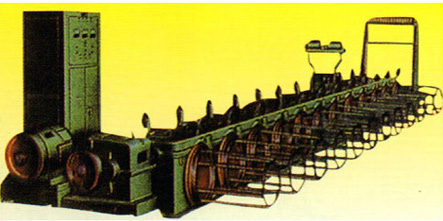

| Hot Dipped Wire Galvanizing Line |

|

|

|

|

| |

|

| |

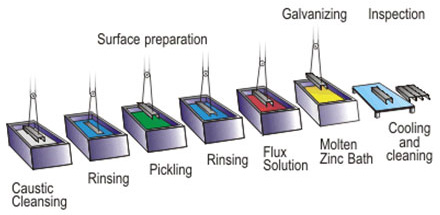

Hot Dip Galvanizing, as a method of corrosion protecting for steel, has grown almost continuously since it was first used over 150 years ago. Its ability to grow in the face of sophisticated competition is the result of the simplicity of the process and the unique advantages of the coating.

Galvanizing can only be performed on chemically clean surfaces. Therefore most of the preparation work is done with this objective in mind. The substrate will usually be dipped in a dilute acid solution to remove all traces of surface oxide such as rust and mill scale. After rinsing, the work is then dipped in a flux prior to galvanizing.

| Hot dipped wire galvanizing line |

Anneal furnace & Acid washing groove |

Zinc pool & furnace |

Wire decoiler and take-up |

|

|

|

Main parameter:

1. Wire diameter: 1.5mm-5mm

2. Output: 30-45 tons/DAY

3. Max. coil weight: 150 kg, the inner coil diameter: 40/50mm

4. Workhouse Size(W*L): 10m*105m

5. Energy: natural gas with 300mpa for outlet

6. Zinc coating: 70---300g/m2

7. Tensile Strength: 350~450N/mm, low carbon iron wire

8. Zinc pool life : 2 years with 450°C

9. Anneal Furnace Weight : 70 tons

10. Zinc furnace weight: 25 tons

11. Power: 50KW |

|

| |

|

Process Flow:

Pay off → lead annealing bath → water quench → Fumeless pickle → "Flash" pre-flux→ Drying → Hot-dip galvanizing → Wiping → Cooling → Vertical take up |

|

|

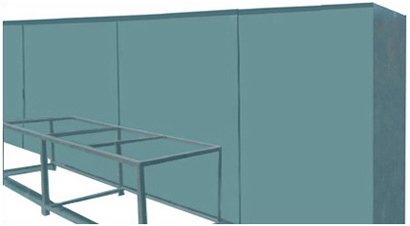

Anneal Furnace with 4 hanging hook:

Length: 18M, Width: 2.5M, Height: 2M

Interior Temp: 1100--1300 °C

In 18 parts

With natural gas burner

T-3 Linear bricks: 12000 pieces

T-3 Light-type heat resistance bricks: 12000 pieces

T-19 Ladder-shaped bricks: 4500 pieces

T-54 Arc bricks: 300 pieces

T-206 Semi Bricks: 300 pieces

36 holes bricks: 44 pieces

High-Alumina cement and powder

5# Angle steel, 8# Angle steel

3mm and 2mm Steel Plate |

|

|

Acid washing groove

L: 9M, W: 1.5M, H: 0.6M |

|

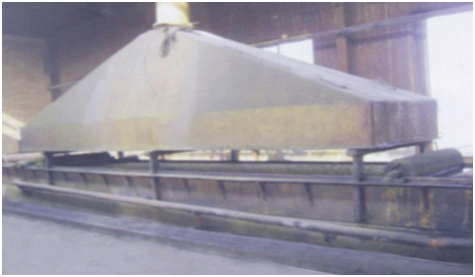

| Zinc pool and zinc furnace: |

Zinc Pool

Thickness: 5CM,L* W*H=3.5*1.6*1.2M

08F 50MM Steel Plate

Capacity: 30 tons zinc block

Zinc furnace with 4 hanging hook:

Length: 5M, Width: 2.5M, Height: 2M

Interior Temp: 1100--1300 °C

In 5 parts

With natural gas burner |

|

|

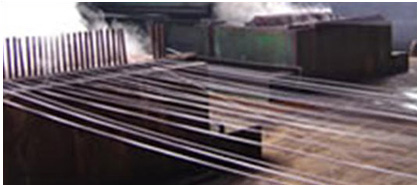

| More picture of hot dipped wire galvanizing line |

|

|

| Wire pay-off of the wire galvanizing line |

|

| Big type of Wire take-up |

|

| Small type of Wire take-up |

|

Item |

Model |

| SS-400 |

SS-600 |

| Winding capstan dia. |

400mm |

600mm |

| Winding capstan length |

600mm |

900mm |

| QTY of the capstan |

24 |

24 |

| Wire dia. |

0.9~2.0mm |

2.0~5.0mm |

| Loading weight |

60~80kg |

80~100kg |

| Winding speed |

10~33m/min |

| Incoming wire height |

1800mm |

2000mm |

| Capstan center distance |

770mm |

1050mm |

| Motor power |

11kw |

15kw |

|

|

|

|

|

| |

|

|