| |

Large movement expansion joint system

Description:

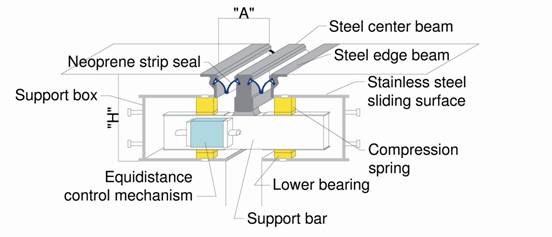

The modular expansion joint is designed for use in heavy trafficked bridge structures requiring movements in excess of 4 inches. This joint system allows the bridge deck to move while maintaining a smooth watertight riding surface. Engineered to last longer than the bridge decks they protect, the joint system longevity comes from the steel multiple support bar system, which combines the strength to support traffic loads and impacts with the flexibility to accommodate continual structure movement. Each joint is made to order and available in two styles, with a box seal, which utilizes a double, layer sealing element and a strip seal .

Features and Benefits:

Watertight

The continuous elastomeric gland prevents runoff water from passing through to the substructure which utilizes two elements for added protection.

Durable Engineered to last as long or longer than the bridge decks they protect.

Versatile Provides a smooth riding surface while absorbing the impact of heavy traffic.

Recommended for:

Sealing joints on bridges with movements greater than 4 inches.

New construction or repair of existing expansion joint systems.

High impact conditions.

Technical data:

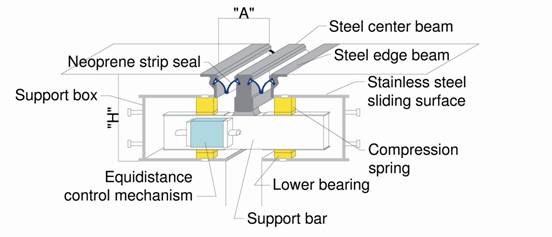

Mechanically Locked Seal The neoprene sealing elements of the expansion joint mechanically locked into the machined edge and separation beam cavity. Each seal is designed to absorb the expansion and contraction movements with its folding action and preformed hinges.

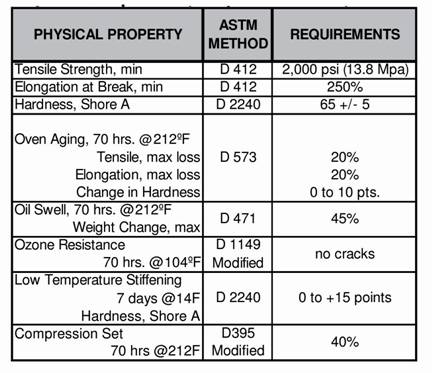

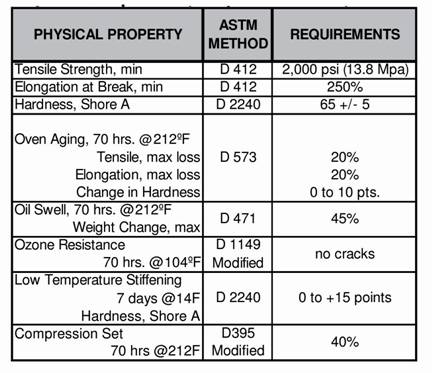

The seals are made of high quality neoprene and are highly resistant to deterioration from exposure to weather, sunlight, and oils. Our joint systems are available with box or strip seal sealing elements. The box seal provides increased rigidity and a double layer of watertight protection. The strip seal sealing element uses an inner-locking single layer, providing watertightness and ease of installation in the field.

Multiple Support Bars Each traffic-bearing separation beam in a joint system has a dedicated support bar in every support box along the length of the joint. The feature of multiple support bars consists of assigning each separation beam its own set of support bars and connecting it rigidly to them. This arrangement will transmit loads to the edges of the joint and at the time, move freely in the direction of movement of the structure.

Rigid Connection Separation beams in the joint system are maintained on support bars bridging the main gap. Each beam is securely fixed to independent support bars and is prevented from tilting due to the action of horizontal loads.

High Rotation Bearings Designers and owners now have the latest high rotation bearing technology available for Standard Modular Systems.

Resilient Support Structure The resilient support structure of the joint system to accommodate thermal movement as well as rotation and deflection of the bridge. Support bars in the joint system ride between specially engineered resilient bearings and springs, which act to dampen the dynamic loading. The bearings support the bar while the springs above the bars prevent looseness, rattling and uplifting.

Movement table:

Physical Properties (Neoprene Rubber):

|