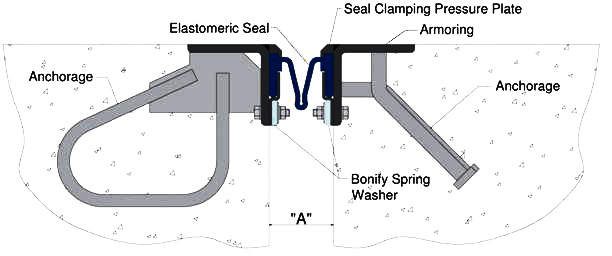

Armored Expansion Joint System

Armored Expansion Joint System

Description:

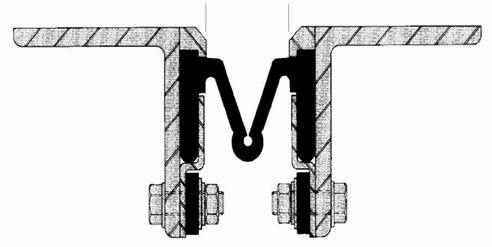

The expansion joint system consists of a heavy-duty steel edge member and a rugged sealing element. The development principle adopted in the system insures that a positive mechanical pressure is maintained at all times between the edge member and sealing element. The system can easily accommodate the high loads of vehicular traffic while effectively sealing expansion joints in bridges and structures with movements up to 175 mm (6-7/8 inches).

Features and Benefits:

Recommended for:

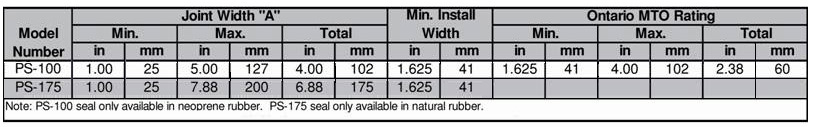

Technical data:

Movement table: